Well known approaches to cancer treatment include surgery, radiation therapy, chemotherapy, immunotherapy, and chemicals. All of these conventional therapies have been and are still being used to treat mesothelioma. While some of these approaches have been successful with other solid tumors, unfortunately, this has not been the case with mesothelioma.

“All these agents can kill cells. . . . Unfortunately, this is not true for mesothelioma, because, as I say, it is a very resistant tumor to … conventional therapy. So, because of that, we try to find … new therapeutic approaches.” – Giovanni Gaudino

One of these important new approaches is aimed at overcoming chemoresistance and interfering with cell survival.

Overcoming Chemoresistance

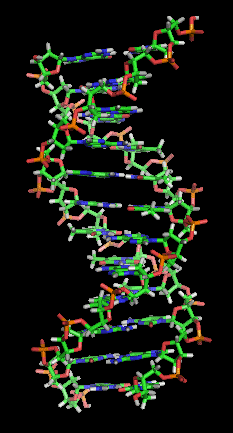

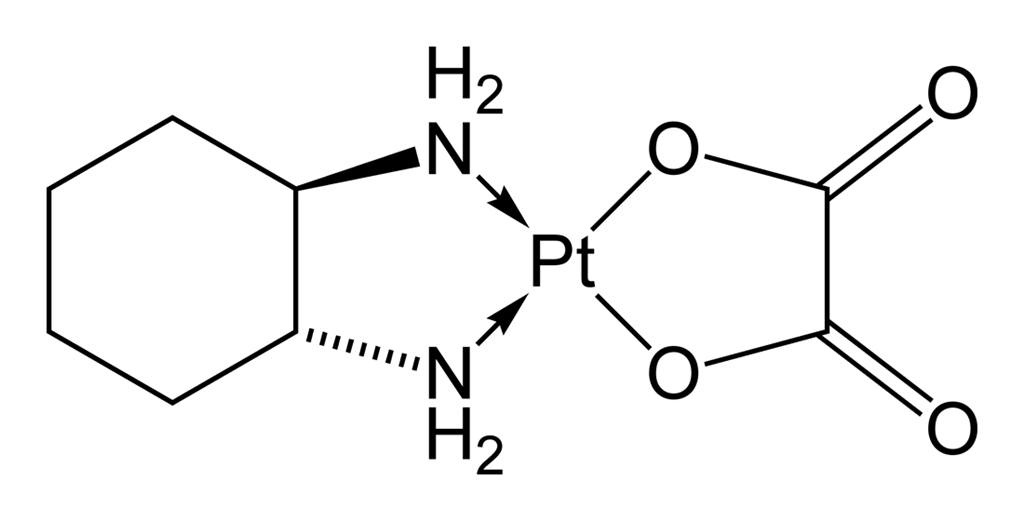

Scientists like Dr. Gaudino have been studying how mesothelioma cells develop; in other words, what has gone awry in the normal cell life of growing, maturing and then dying off. Dr. Gaudino points out that the growth signals that lead to cancer cell proliferation and neoplastic transformation are the result of a series of biochemical reactions that start at the cell’s surface and move down in a multi-step process called “receptor downstream signaling.” This continues until the signals reach the nucleus of the cell and their final destination, which is the DNA. The DNA is the “port master” of all that is going on in the cell. The “big button” on the top of the cell membrane is called the “Receptor Tyrosine Kinases.” It mediates the process by which cells become resistant to cell apoptosis, or what is known as “programmed cell death.” Apoptosis is a normal process of getting rid of old cells. In an average adult human, 50 to 70 billion cells die every day as a result of apoptosis. In patients with mesothelioma as well as other cancers, there is insufficient apoptosis, and there is cell proliferation of abnormal cells.

“So the rationale of our work was that the Receptor Tyrosine Kinases, which is the big button that you see on top of the handle of the cell membrane, can be a good target, and by inhibiting [the] receptor downstream signaling . . . we could get rid of the tumor chemoresistance.” – Giovanni Gaudino

The purpose of the drugs used to target this button, then, would be to interfere with cancer cell survival and chemoresistance.

Cell Survival

There are many different molecules involved in cell survival and apoptosis. These molecules are on the surface of the cell, in the interior of the cell, and in the nucleus. These molecules all have names so that they can be identified. Thus, if someone is exposed to asbestos, this toxic exposure combines with genetic factors and many other different reactions. These different reactions are all pathways that determine cell survival and the transformation of normal tissue to tumor cells which results in cancer, in this instance, malignant mesothelioma.

“And, cell survival is a very important step for a cancer, because if [a] cell can survive despite all the DNA mutations, the DNA damage they suffer, it means they have a good chance to become tumor cells and to .. [become] cancer.” – Giovanni Gaudino